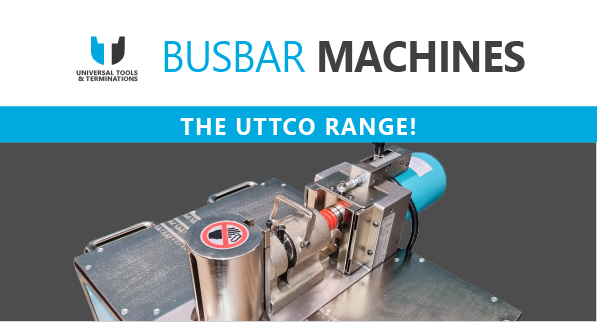

Maximise the Instant Asset Write-Off opportunity with the UTTCO Busbar Machine Range!

The $150,000 instant asset write-off still applies on all new and second hand assets!

This has been extended up to the 30th June 2023.

Do you need to invest in new tooling or machines for your workshop?

See below the UTTCO range of busbar bending, punching and cutting machines! For more information on a machine, simply click on the links below to view in our website. Or contact our friendly sales team today with your queries.

Learn more about the Instant Asset Write-Off HERE.

Get in touch with the team today for pricing CLICK HERE

KUDOS Busbar Bending, Punching & Cutting Machines:

– Busbar Puncher 70mm throat

Part Number: SH-70A

Features:

- Busbar punch 70mm throat c/w punch & dies 10.5, 13.5, 17.5 and 20.5mm.

- Max 12mm thickness copper busbar

- Made in Taiwan

Part Number: DBBN-120

Features:

- Bending busbar up to 120 x 12mm

- Operated by any hydraulic pump with rated oil pressure of 700 bar (1,000 psi)

- Vertical stand ideally suited for bending solid copper and aluminium busbars

- Made in Taiwan

Part Number: HYBC-120

Features:

- Vertical stand ideally suited for cutting solid copper and aluminium busbars

- Operated by any hydraulic pump with rated oil pressure of 700 bar (1,000 psi)

- Made in Taiwan

ERKO Busbar Bending, Punching & Cutting Machines:

Part Number: SH400

Features:

- Station for Al & Cu busbars precise cutting, bending, hole punching, inserting nuts and offsetting.

- Busbar width up to 120mm

- Busbar thickness 12mm

- Busbar angle range up to 90°

- Equipped with easily adjusted bending angle sensor, measuring rulers, height adjustable punching head and built in hydraulic pump

- Made in Poland

Part Number: SH900PLC

Features:

- Station for Al & Cu busbars precise cutting, bending, hole punching, inserting nuts and offsetting.

- Busbar width up to 120mm

- Busbar thickness 12mm

- Busbar angle range up to 90°

- Equipped with LED touch screen programmed in English

- Made in Poland

DGR Busbar Bending, Punching & Cutting Machine:

Part Number: ES-125

Features:

- Capable of bending, punching and cutting up to 125mm high busbar x 12mm thick

- Mobile machine and can be wheeled around or taken out on site

- Comes c/w: Hand and foot switches, Punch & Dies 6.6mm, 9mm, 11mm, 14mm and 16.5mm

- Adjustable bending and punching heads – can be raised and lowered by the wheel

- Angle reader for auto cut-off when the desired angle is reached

- Made in Turkey

To invest in quality tools like ours and take advantage of the instant asset write-off, contact our friendly sales team today!

Call us on (03) 5579 5841 or send an email to sales@uttco.com.au.